Sign point is manufacturer and designer of all types’ fire & safety signs according to the international standards and regulation.

Sign point helms by a team of experienced competent marine engineers and graphic designers. The engineers have vast experience on servicing and maintenance of fire and safety equipments and risk assessment on relevant field. On their experience on various international regulations they assess various risks and plan your premises safety way guidance system and plan the fire escape routes. The well graphic designers with experience on designing fire escape routes designs the fire safety plan and fire escape routes, design as per the guidance of ISO, ISM AND OHSAS complied symbols

SAFETY SIGNS and symbols are important safety communicating tools. They help to indicate various hazards that present in the area. At the same time, it informs the presence of hazards. It is very important in reducing accidents in the workplace more obviously in manufacturing, heavy industry, hospitals, malls and high rise buildings. It gives a general safety message, through a combination of colour and shape and which, by addition of a graphical symbol, give a particular message. They are used at high, low and intermediate locations in a Safety Way Guidance System to guide the evacuee at contingency

photoluminescence is the emission of light from any form of matter after excitation from another light source. Time periods between the absorption and emission can vary greatly from milliseconds to minutes. Similarly, the degree of luminance and its longevity can vary depending on the level of excitation achieved. The real beauty of photoluminescent products, in the context of a Safety Way Guidance System, is that they do not need electricity to glow in the dark if properly sited and maintained. In an emergency situation where a mains failure has occurred, they will immediately light the way to safety even in smoke conditions

Daylight

darkness

A good safety way guidance system communicates the necessary information to allow people to evacuate a building effectively (i.e.in a consistent and coherent manner) to a designated safe area in the event of an emergency.

Safety Way Guidance Systems in themselves cannot be standardised as every building and set of occupants are different. What can be standardised however is the methodology used to design a SWGS and the way the information required is presented.

When designing a SWGS you will need to carry out a risk assessment to determine what class of photoluminescent product you require as each class has its own unique characteristics. For example, if you need your photoluminescent to emit its light quickly and do not need it to glow brightly for more than 20 minutes you may choose Class C product. However, if you need a photoluminescent product that is effective for over 2 hours you may decide to choose a Class G.

Below is a list of SWGS components which should be considered after any risk assessment concluding that a Safety Way Guidance System could reduce defined risks in the workplace.

- At high location (1.8m to ceiling level) to indicate the direction of the escape route, changes to the escape route path and final destinations at medium to long observation distances (10m-30m).

- At intermediate location (1.2m-1.8m from floor level) to visually reinforce the message of high location signs along the escape route, identify hand rails/central supports and other features at exits to be used in emergencies. Observation distances between 10m and 20m. Including

- Door opening mechanism signs; light switch markers.

- At low location (below 1.2m to floor level) to provide a continuous, conspicuous line from any point in the building to the final destination, preferably delineating the boundaries of the escape path for up to 10m. Including-

- Arrows in dots; plain dots.

- On emergency exit doors including the final emergency exit door around the door frame to show which doors are part of the escape route.

- On stairs, ramps or ladders at low and intermediate location, if appropriate, to indicate the pitch line of the steps, outline of each step or highlight a ramp gradient

Fire Escape Route Safety Signs

- Fire Equipment Safety Signs and Safety Equipment Signs at intermediate height near to the location of the equipment to identify what type of equipment it is and its purpose such as fire extinguishers.

- Warning Safety Signs at intermediate height to indicate the nature and location of potential hazards such as electrical equipment or obstacles on the escape route such as pillars.

Other Safety Signs

- Fire Equipment Tapes to outline fire equipment on or near to the escape route.

- Hazard Tape to outline potential hazards on or near to the escape route

Other Safety markers

- Fire Equipment Safety Signs and Safety Equipment Signs at intermediate height near to the location of the equipment to identify what type of equipment it is and its purpose such as fire extinguishers.

- Warning Safety Signs at intermediate height to indicate the nature and location of potential hazards such as electrical equipment or obstacles on the escape route such as pillars.

Other Safety Signs

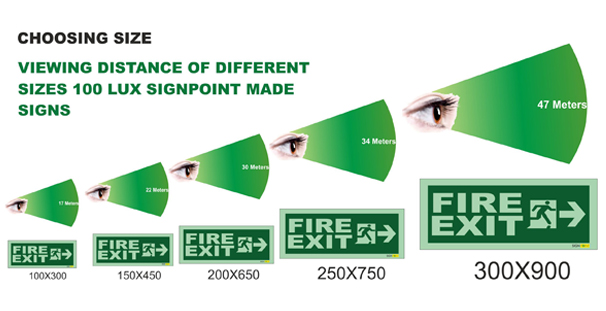

- Sign point Fire Exit and Exit signs are required to show evacuees the shortest escape route from a building. Fire exit and exit sign conform to international standards to ensure consistent understood design and format.

Sign point Exit & Fire Exit sign

With recent developments in Codes and Standards for Photoluminescent Safety Products and in line with the recognized industry development the ISO standards of minimum luminance standard of photolumianscent stickers as follows

Luminance decay characteristics of photoluminascent safety signs as per the regulation

- Luminance mcd/m 2

- 2 mins

- 10 mins

- 30 mins

- 60 mins

- Class A

- 108

- 25

- 7

- 3

- Class B

- 210

- 50

- 15

- 7

- Class C

- 690

- 140

- 45

- 20

- Class D

- 108

- 25

- 7

- 3

- Class E

- 1800

- 400

- 120

- 55

- Class F

- 2300

- 520

- 155

- 70

- Class G

- 3000

- 650

- 190

- 80

STAGE 1 - Risk Assessment The first stage in initiating towards an effective safety management policy is for any manager, owner, occupier and/or nominated contractor to undertake a formal risk assessment. Risk assessments, including risk management and audits are the fundamental requirements of the Health and Safety (Safety Signs and Signals) Regulations and the Regulatory Fire Safety standards & requirements .

The display of relevant signs in conjunction with a risk assessment indicates a compliance with these requirements. The purpose of a formal risk assessment is to:

- Identify the nature of risk that may cause harm to employees and/or visitors within your premises.

- Qualify the likelihood or possibility of any occurrence or incident likely to cause injury or harm to employees or visitors within the confines of your premises.

- Define the measures, steps or actions needed to be taken to prevent the possibility of any occurrence likely to cause injury or harm to employees or visitors. Liaise with emergency services and create an emergency plan.

Compile a list of hazards that may be present within your workplace/premises. In small premises, a practical way to do this is to stand in the middle of the room that you are assessing, fix your attention on a point on the perimeter of the room, then turn slowly through 360 degrees making a note of the obvious hazards you can see. In larger premises, a team approach to identify hazards may be more effective especially if you draft in an expert for advice.

1. Instant illumination in the event of a power loss e.g. daylight charged phosphorescent materials or electrical systems.

2. Escape route identification.

3. Directional information at change of level, elevation or turn.

4. Hazard and obstacle identification and location.

5. First aid and fire fighting equipment identification and location.

6. Handrail and stairnosing illumination e.g. daylight, charged phosphorescent or electrical systems.

7. Emergency exit and escape equipment illumination and operating procedure identification.

8. Visual orientation cues and emergency instruction.

Whilst some of the above can be achieved through good emergency lighting systems, a good safety way guidance system would complement the illumination with low proximity supplementary components